If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.Ī: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible. SMT nozzles, nozzle cleaning machine, nozzle filterĪ: We usually quote within 8 hours after we get your inquiry. If you need to have more information, remember to do not hesitate to contact us by E-mail or telephone.Ī: Our company deal in the following products: Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for High Performance Smt Reflow Oven Pcb Conveyor - PCB Fast Prototype Reflow Oven IN6 – Neoden, The product will supply to all over the world, such as: Latvia, Chicago, Montreal, We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to offer you the best service. Related Product Guide: Defect analysis of reflow welding PCB soldering temperature curve can be displayed based on real-time measurement With 6 heating zones (upper3/down3), NeoDen IN6 support most of regular components, LED and ICs.ġ.Full heat convection, excellent soldering performance.įlexibly convert from Celsius to Fahrenheit, easy to understandģ. Different from the traditional technology, NeoDen IN6 adopt our original design of built-in soldering smoke filtering system, which is more eco-friendly. NeoDen IN6 is a desktop soldering machine with excellent soldering performance. NeoDen IN6 has 6 temperature zones, a built-in welding smoke filtering system, working file memory function and heat-up reminder, which makes it intelligent and innovative and compact. IN6 is a newly designed and manufactured reflow oven by NeoDen Tech. High Performance Smt Reflow Oven Pcb Conveyor - PCB Fast Prototype Reflow Oven IN6 – Neoden Detail: Remember to note that samples are available before we start our business enterprise. We are going to reply you when we receive your inquiries. The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for Smt Pcb Nozzle, Nozzle, Smd Pick And Place Vision, Please sense no cost to speak to us anytime. Copying this project isn’t (doing your own may be from a learning point of view).Product Detail FAQ Product Tags Related Video Feedback (2) Reminds me of the various lathe & mill groups where they spend all their time modding their machines – not actually doing anything useful.ĭecide what’s useful. Same for building power supplies, Tx/Rx stuff etc. After a while many decisions come down to “buy vs build”, and temperature controllers fell into the “buy” category years ago. You get a case, power supply, probe (usually), ADC, uC, displays, relays and other assorted parts.ĭIY will cost you hours of work and at least $50. Look at the $15 eBay PID as a pile of parts. Yeah, it doesn’t get the profile right but that’s rarely critical in the DIY realm (and getting the profile right is a bit more complicated than just changing the temperature). PID triggers an alarm at a set point, that trips the timer. That said I’d never build a temperature controller, even thought I know how PID works, I can program a uC etc. Sure, learning something is always fine, and controlling an oven is pretty simple project in the scheme of things. Posted in Tool Hacks Tagged fpga, max31855, papilo, reflow Post navigation It includes an SPI interface, display driver, and the temperature state machine logic.

#Prototype reflow oven code#

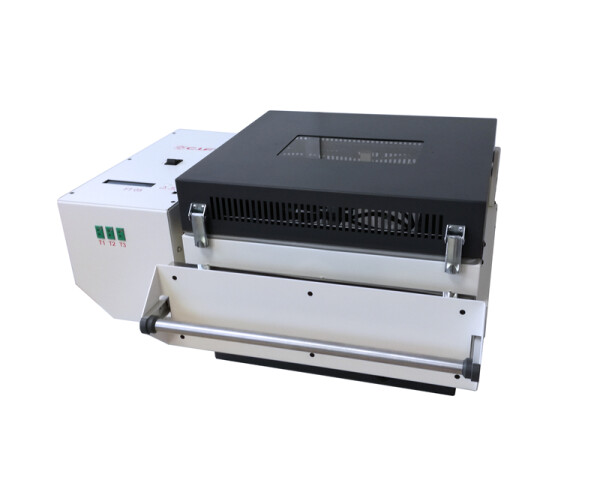

The VHDL code that drives this oven is linked in the writeup, and has some interesting bits for those looking to experiment with FPGAs. To control the heater, a 40A solid state relay is used. This device provides amplification, cold junction compensation, and analog to digital conversion which spits out the temperature over SPI. The oven uses a MAX31855 to read temperature from a thermocouple. It implements a state machine that meets the reflow profile of the solder paste, ensuring SMD components are soldered properly. This build uses the Papilo One FPGA development board as a controller. Most of those projects use a microcontroller to do closed loop control, sensing the temperature and toggling the heating element to hit a set point. We’ve seen plenty of reflow oven builds in the past.

Later that day, he tore it apart and built this FPGA controlled reflow oven.

For Christmas, ’s wife gave him a mini-oven.

0 kommentar(er)

0 kommentar(er)